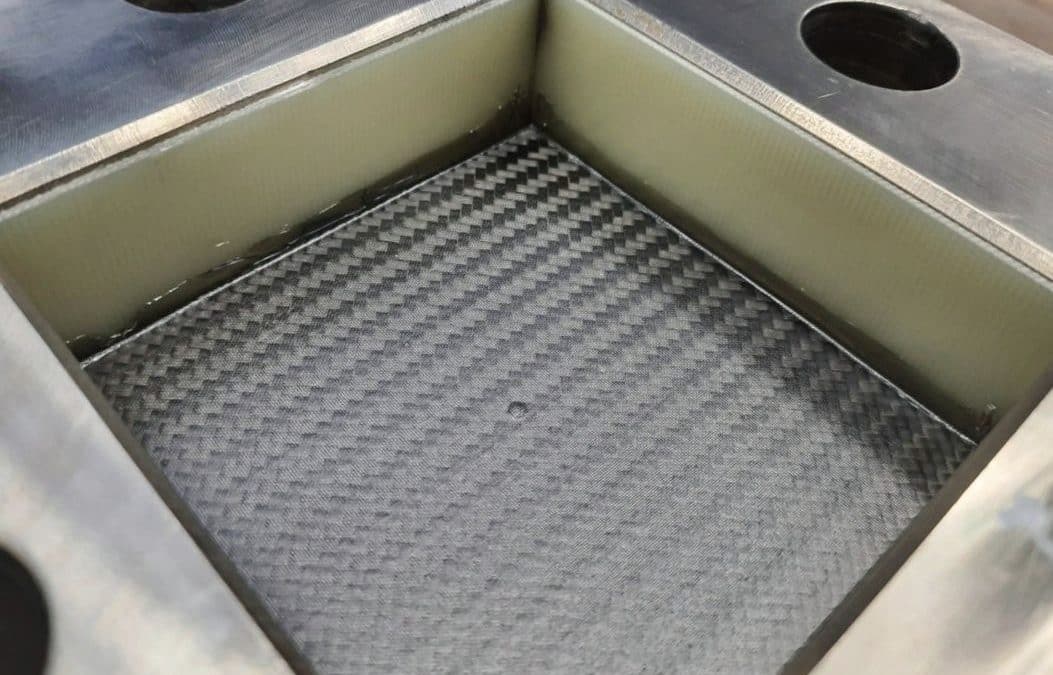

<img src="https://naked-science.ru/wp-content/uploads/2025/03/Obrazets-issleduemogo-kompozitnogo-materiala.jpg" alt="Perm scientists have found a way to avoid defects in composites at the production stage"/>In recent years, thick-walled structures made of composite materials have been actively studied and introduced into industry. These are durable and lightweight products based on polymer and continuous carbon or glass fibers. They are needed to operate under high loads, which are subjected, for example, to elements of aircraft, missiles and submarines, wind turbine blades, gas cylinders and much more. Such structures are created in an autoclave – a large oven where layers of material from fibers and resin are laid out in a given shape, and then pressed under high pressure and temperature into a finished product. However, due to the large thickness of the walls, the material can be compacted unevenly, which leads to various defects. Scientists from Perm Polytechnic University have established optimal modes for preliminary forming of a workpiece in an autoclave. They will provide better compaction of the material and allow control over the thickness of the layers, which will improve the quality of the finished product.

Perm scientists have found a way to avoid defects in composites at the production stage